MSU poultry science department adds biosecurity level 2 lab

Contact: Vanessa Beeson

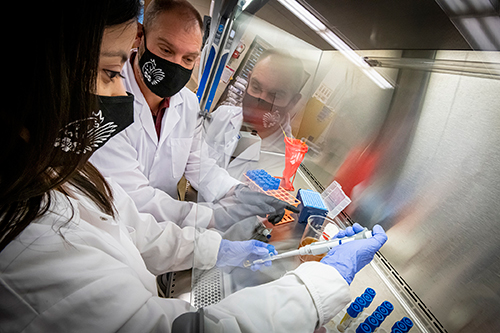

STARKVILLE, Miss.—Mississippi State’s poultry science department is now equipped with a new laboratory for conducting biosecurity level 2 research.

The department’s Animal BioSafety Level (ABSL)-2 facility, which opened last month, provides a distinctive setting for investigating and conducting research on pathogenic bacteria that affects the poultry industry.

Mary Beck, professor and head of MSU’s Department of Poultry Science, said the ABSL-2 lab enhances the department’s commitment to serve the Mississippi poultry industry through the land-grant mission of education, research and outreach.

“We are extremely excited for our department and MSU to have this facility come to fruition. This space, which was funded by the university’s Mississippi Agricultural and Forestry Experiment Station, will help our scientists conduct research vital to this state’s most important agricultural industry,” Beck said.

Earlier this year, National Chicken Council and the U.S. Poultry and Egg Association reports indicated that Mississippi’s poultry industry had an annual impact of $20 billion on the state’s economy and employed 28,500 growers and employees generating $1.5 billion in federal, state and local taxes.

Beck explained how the facility will accommodate research that benefits the industry as a whole, from the egg to the plate.

“This lab mimics a setting you’d find in the poultry industry, which allows our scientists to evaluate different aspects of disease and infection as it affects birds throughout their lifecycle from in the egg, to grow out, and ultimately harvest,” Beck said.

Researchers, including faculty and students, are trained on health and safety protocols and procedural safeguards that have been implemented to protect people and animals alike. The facility includes six individual rooms for housing battery cage and floor pen trials, a research lab to culture and study pathogens, separate screening rooms complete with sinks and sanitation stations, an autoclave, and restroom and shower facilities. Every room is fitted with a separate HEPA-filtered air handling system. Digital controls allow for the reliable control and maintenance of appropriate temperatures, lighting and humidity.

Professor Aaron Kiess, who spearheaded the effort to bring the lab to MSU, said the facility will help researchers find better ways to prevent and treat infections caused by Salmonella, Escherichia coli, Campylobacter and Clostridium bacteria, aiding an industry that is a vital component of food security.

Kiess said the lab provides a chance for researchers to help the poultry industry improve management strategies in disease prevention and mitigation.

“As the industry moves to a ‘no antibiotics ever’ program, now more than ever, it’s critical that we find an alternative to antibiotics, so the poultry industry can maintain safety and health of their birds for the public,” Kiess said. “If we could find antibiotic alternatives that inhibit infectious diseases caused by pathogenic organisms, this could reduce mortalities and improve bird health, leading to improvements in growth performance and ultimately more profit.”

In addition to MAFES funding, contributions to the facility were made by international animal health company Huvepharma, Inc., with all light fixtures, bulbs and dimmers provided by www.aglights.com and Overdrive Lighting.

For more information on MSU’s Department of Poultry Science, visit www.poultry.msstate.edu.

MSU is Mississippi’s leading university, available online at www.msstate.edu.